Cordless Drill Battery Articles

https://www.drill-batteries.com

I don't have a fancy battery tester. How can I test my batteries?

It's possible to get a ballpark figure of you battery's performance by timing how long it takes to discharge in a tool that draws current at a relatively constant rate, like a flashlight or fan. A high draw tool such as a leaf blower or vacuum could also be used, but these not only requires more precise timimg, but the results are likely to be lower than rated (even for a new pack) because of the high discharge rate. The most accurate results will come from a tool for which one expects the discharge to last one hour (or longer). A tool like a drill or saw would be a poor choice because they're not designed to be used for long unloaded, and it would be very difficult to provide a contant load.

It's safer to test Lithium Ion packs than NiCads because of the built-in protective circuitry which prevents the cells from overdischarging. NiCad packs lack this circuitry and can therefore be completely discharged if not monitored carefully. (Note: It's not necessarily harmful to fully discharge a NiCad cell, but with 15 NiCads in series it's unlikely that they're all be completely discharged at the same time. Some cells will discharge before others and may actually "reverse" while others are still discharging and this can be harmful. Ideally you'd want to stop discharging a NiCad cell when it reaches about 0.9v, or 13.5v for a healthy 18v pack.)

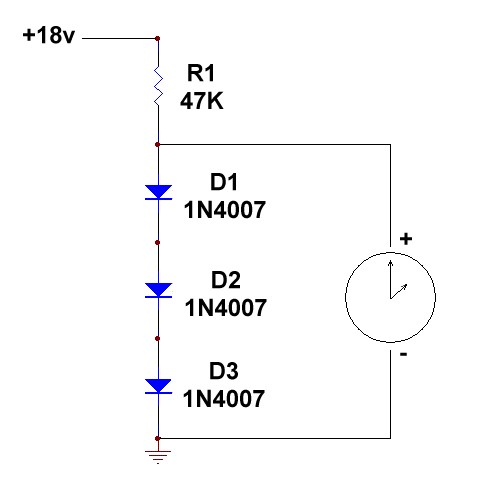

You don't need to do this, but I built a special gizmo for timing exactly how long a Ryobi 18v battery operates before it dies. I gutted a dead P104 battery pack and sacrificed a cheap analog watch. I cracked open the watch, removed the 1.5v button cell battery, soldered bell wires to each of the battery contacts, put some heat shrink tubing around the wires, and drilled a small hole through the watch cover for the wires to exit. On the bottom of the pack I mounted a pair of banana plug receptacles (input) and then glued on the watch with the wires entering the pack through a small hole. Inside the pack, I directly connected the inputs to the outputs on the neck of the cell. I also wired in the press-button power gauge. I connected a 47K Ohm resistor and three 1N4007 diodes to the positive (+) side, and that last diode to the negative side (-). (Pretty much any diode would have worked, I picked 1N4007 because I had a spool of 100 lying around in my shop.) The watch battery leads I connected to the negative (-) side and to the junction between the 47K Ohm resistor and the first diode. This battery "shell" plugs into any Ryobi 18v tool.

I then set the time on the watch to just before 12:00. When I connect a Ryobi 18v battery to the input terminals, the watch starts to run. If it's not already on, I switch on the Ryobi tool, then wait. There's about a 0.5v drop across each diode, so as long as the battery has a charge, 1.5v runs the watch (and this circuit draws a negligible 0.4 mA from the pack). When the battery is depleted the Ryobi tool and the watch both stop. So long as the run time is under 12 hours, all I have to do is record the time on the watch to determine how long the battery operated the tool.

You can use the table above, a tool, and a clock to get a ballpark figure of your battery's capacity. For the most accurate estimate, select the tool with the lowest draw. For example, say you have a P3300 Fan and a P103 battery. The Fan on Low draws about 200mA and the P103 is rated 1300mAh, so it should run the fan on low for about 1300/200=6.5 Hrs. Now connect your fully charged pack to the fan on low and clock how long it takes before the fan stops. Stop by the fan every 15 minutes or so (during commercial breaks?) and write down the time. When you notice that the fan has stopped running, you know the pack ran out sometime between the last reading and the current time. If you're checking often enough, this should be a good estimate. If your battery is within 10% of the figures above your drill battery is probably fine. If it operates the tool for significantly less time, you may want to start thinking about getting a new pack. I wouldn't trust results for any device where you determined that the discharge should take less than an hour (e.g., vacuums, leaf blower), I included them here just to demonstrate how much current these devices draw as compared to other tools.

Also, I've noticed that new batteries tend to operate below their full capacity for the first few cycles. If your battery tests within 80% of full capacity on the first discharge cycle, it's probably fine. If you test it again you should notice 5-10% improvement on the second time and even more on the third.

Perhaps you've heard of the "Flashlight Test", which is supported by the data in the above table. According to the "Flashlight Test" a P103 should run a flashlight for 2 hours, a P100 for 3 hours, and a P104 for 4 hours. As per the table above, the P103 should go just over 2 hrs and a P104 just under 4. I don't have a P100 to test, but I'd extrapolate the P100 duration as 1700/600=2.833 hours or just under 3.

© Copyright 2010-2024 All Rights Reserved